top of page

CASE STUDIES

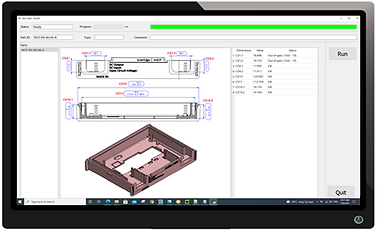

Critical Dimensions Inspection of Incoming Components

We manufacture millions of products each quarter on its multiple fully-automated assembly lines. We are constantly looking for ways to improve raw material inspection capabilities in order to further improve the manufacturing yield.

Saccade Vision has demonstrated in a very short time excellent performance, flexibility in inspection of multiple components, helped us to increase the testing coverage and provided valuable insights on raw material quality.

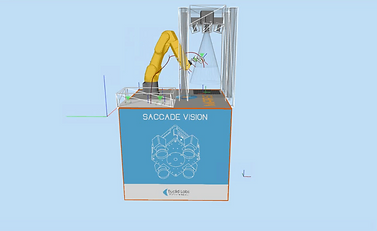

Flexible Automated Inspection Solution For Metalworking Machines

We saw that the Saccade sensor is a different product, not simply better or faster than the existing ones.

It gives us the flexibility that our software can leverage to simplify the design and implementation of complex inspection systems.

Gallery

All Categories

bottom of page